Historically, the frequently utilized method for deciding residue limitations relies to the Fourman and Mullen method, also called therapeutic dose–based calculation.11 Together with a visually clear surface area, this strategy makes use of the more stringent of the following two criteria:

, thirteen Several pharmaceutical corporations go on to support the dose-based mostly calculation. On the other hand, latest marketplace publications and regulatory changes affecting mostly European nations around the world are leading how to a unique method, called the overall health-based mostly calculation.14

Doc learnings throughout the cleaning development course of action to ensure awareness transfer, and make use of them to build an in depth cleaning process. Use chance evaluation applications to identify any prospective challenges with regard to the cleaning method and make the required changes.

Defining acceptance conditions remains Probably the most challenging aspect of a cleaning validation software.

Conduct swab/wipe sampling on regions identified in the hazard assessment and especially on identified most difficult to wash places.

Then only swab sampling shall be completed and also the cleaning validation exercising shall be concluded depending on the result of the swab sampling only.

products and solutions for which visual inspection can't be get more info accustomed to estimate cleanliness with the gear, indicating HBEL derived residue concentrations can't be visually detected

Phase 2 - Cleaning process qualification: Appraise cleaning procedures to make sure They can be helpful and cleaning validation in pharma reproducible. Cleaning method qualification scientific tests entail conducting cleaning verification assessments a predetermined range of occasions below specified ailments.

Regime or periodic sampling needs to be laid out in the cleaning method and recorded. The type of sampling, quantity of samples, sampling frequency, and analytical tests may perhaps range for every cleaning method. The regimen or periodic sampling approach provides a smaller sized range of sampling details as opposed to validation sampling strategy depending on the effects of your validation analyze and threat assessment.

Preventive maintenance need to include a calibration process for measurement units for instance pounds scales, thermometers, flow cells, conductivity and pH probes, and also other tests devices used in the cleaning procedure.

Pharmaceutical Inspection Cooperation Scheme - Inquiries and responses on implementation of danger-based mostly avoidance of cross-contamination in output and 'Guideline on setting wellness-dependent publicity restrictions to be used in danger identification while in the manufacture of various medicinal solutions in shared facilities' (PI 053-1).

an Lively ingredient that is definitely for veterinary use and that's not an active pharmaceutical ingredient;

Use QRM principles to ascertain: the necessity for which include microbiological and/or endotoxin contamination analysis as Portion of verification/qualification and on-going checking assessments

Gear really should be dry just before storage by an ideal method of drying as per SOP or let all the drinking water to empty from the devices and its parts.

Jonathan Lipnicki Then & Now!

Jonathan Lipnicki Then & Now! Ross Bagley Then & Now!

Ross Bagley Then & Now! Val Kilmer Then & Now!

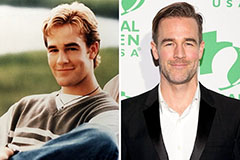

Val Kilmer Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Julia Stiles Then & Now!

Julia Stiles Then & Now!